BioScrub by Energy Cube

Biogas Energy Recovery

Energy Cube builds alternative H2S treatment systems using an iron sponge and controlled air injection. Our iron sponge systems work especially well as a primary H2S treatment system where the incoming H2S in biogas is relatively low or as a backup system to another removal process where a secondary polishing filter is necessary to meet emission standards or engine manufacturer requirements.

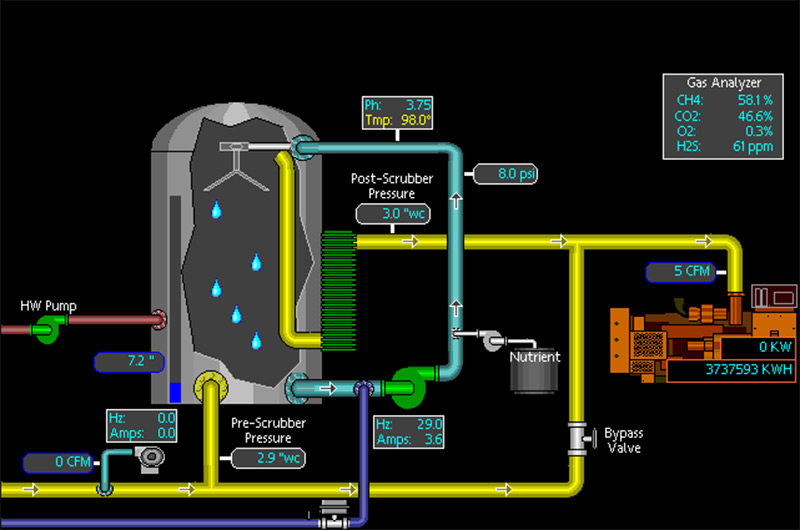

BioSrub represents a breakthrough in biogas energy recovery because it captures the H2S from the gas stream without adding any off-site products. This not only reduces on-going operating costs, but also avoids adding an additional waste stream. No consumable media is added. The H2S is simply transferred from the biogas back to its source.

BioScrub uses oxygenated effluent as the reactor medium. As the biogas passes through the BioScrub reactor, the H2S is absorbed into the activated effluent and is in turn, converted to elemental sulfur. The sulfur-laden effluent then returns to the lagoon.

BioScrub lowers the H2S content in the gas stream to within engine manufacturer’s warranty requirements. It reduces maintenance costs by extending the intervals between oil changes and engine overhauls; and it adds years to the life of your engine.

Contact Us